BFT Rack and Pinion Slide Gate Opener Pros

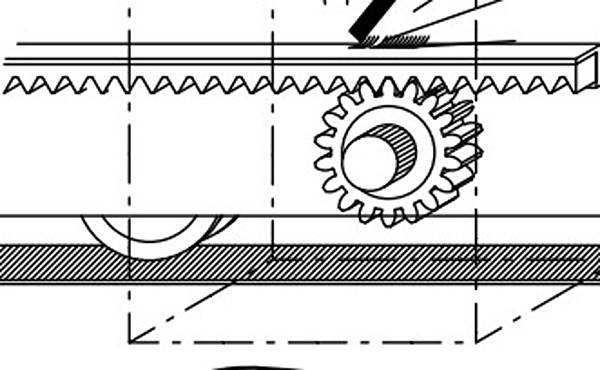

Rack and pinion slide gate openers have a rack with teeth spanning the length of the gate and a pinion, or gear, mechanized on the opener. The rack is bolted to the side of the bottom of the gate frame with the teeth pointing downward. The pinion, or gear, interacts with the teeth on the rack to move the gate back and forth or open and close.

Applications of BFT Rack and Pinion Slide Gate Openers

Rack and pinion slide gate openers, which are popular in Europe, are commonly used in warmer climates and can withstand heavier loads and more frequent use.

Key Benefits of BFT Rack and Pinion Slide Gate Openers

- Handles heavy loads

- Withstands frequent use

- Smooth operation: precise & controlled movement

- Noise reduction

- Little maintenance required

- Noise reduction

- Irreversible: cannot be pushed & stops upon obstruction

Drawbacks of BFT Rack and Pinion Slide Gate Openers

- Installation: requires more consideration & modification

- Suited for warm climates

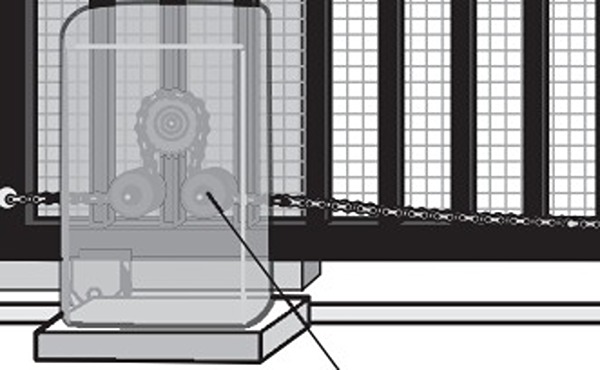

How BFT Chain-Driven Slide Gate Openers Operate

Chain-driven slide gate openers utilize a chain attached to both ends of the gate by a bracket. The chain runs the length of the gate through two idlers and a power-driven gear.

Applications of BFT Chain-Driven Slide Gate Openers

Chain-driven slide gate openers, which are more popular in North America, are better suited for cooler climates because the suspension of chains can better handle large debris like snow.

Key Benefits of BFT Chain-Driven Slide Gate Openers

- Easy installation

- Suited for any climate

- Better suspension

Drawbacks of BFT Chain-Driven Slide Gate Openers

- Noise

- May leave grease line in driveway

- More frequent maintenance

- Less precise and controlled movement